Celebrating Connections: Highlights from MODEX and GTC

At InOrbit, we're more than just providers of cutting-edge RobOps solutions; we're active participants in the vibrant community of innovators and thought leaders shaping the future of robotics. Recently, we had the pleasure of attending two of the industry's premier events: MODEX 2024 and GTC. These shows provided us with an invaluable opportunity to connect with partners and customers, delving into the operational benefits of effective data and fleet management. Join us as we take a glimpse into the InOrbit experience and the connections we made along the way.

MODEX where Innovation Meets Collaboration

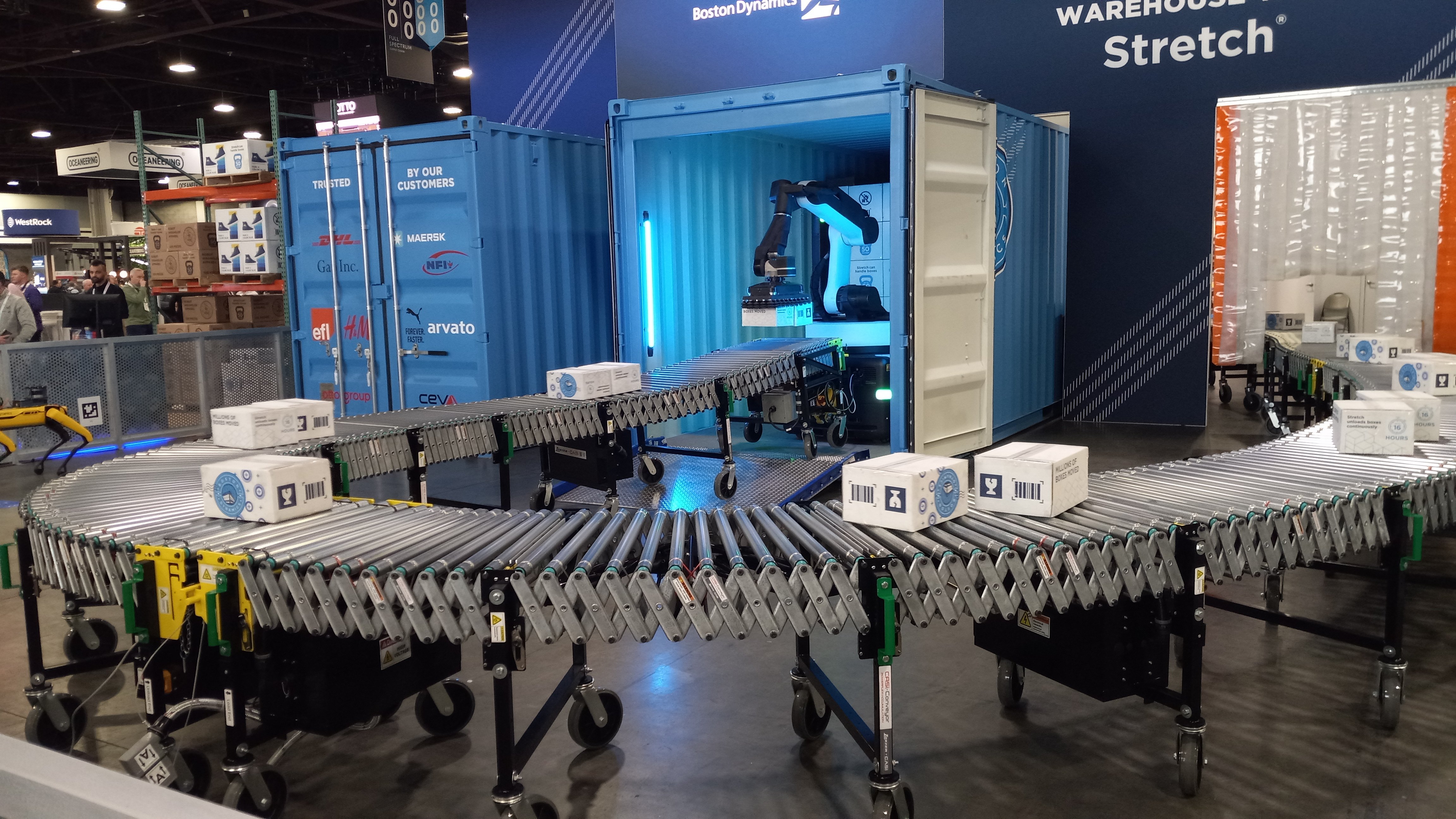

MODEX 2024 was a whirlwind of excitement, with innovation around every corner. It’s referred to as a full-spectrum supply chain conference because it brings together the entire supply chain ecosystem. Unsurprisingly, as the show has evolved over the years it has moved from an orthodox manufacturing focus heavily into robotics. From advanced mobile robots to cutting-edge warehouse management tools, and every forklift you could ever imagine under one roof, there was no shortage of groundbreaking tech to explore.

|

|

|

|

|

|

|

As we mingled with industry experts and customers we had the opportunity to connect, share insights, and explore the latest trends in logistics and supply chain. More than ever the conversations we had underscored the importance of RobOps in shaping the future of supply chain automation.

|

|

|

|

|

|

AI was a major topic of discussion, just as it was during ProMat last year, but rather than just focusing on AI hype with new flashy announcements, this year companies on the show floor worked to showcase effective integration strategies. Both Locus and Covariant had AI-driven integrations on display that were built to address actual problems. Additionally, warehouse digitization is an ongoing struggle for many as diverse technologies require orchestration to work in harmony. Connection points are still the biggest challenge many in the supply chain face. Great robots are being produced, like the newest SlipBot which took home the MHI innovation award this year, but the conversations we had made it clear: It doesn’t matter how fast a truck is unloaded if the pallets sit on the dock waiting for a worker to manually dispatch AGVs to move them elsewhere for unpacking. Thankfully those are exactly the kind of connections InOrbit can tackle.

Our highlight for the show had to be the ⚡Recharge Pizza Party ⚡we threw alongside partners from Wiferion, a Puls brand. Our InOrbit Connect partners had some truly impressive in-process wireless charging tech on display at the Puls booth, like (our favorite) the etaLINK 3000. That’s contactless 3 kW inductive charging - perfect for AMRs. It was great to share a slice and charge up with some friends on the floor.

|

|

|

|

|

|

We could drone on about MODEX, but suffice it to say the show was a huge hit and the InOrbit team was thrilled to be there. For much more detail and an exploration of the show floor, check out our MODEX video below with marketing master Geoff Chapman.

GTC: Embracing AI and Accelerated Computing

Back in the Bay Area the week after MODEX, we took part in another massive event. The GPU Technology Conference 2024 marked NVIDIA’s first foray back into hosting a live event of this scale in several years.

InOrbit made news earlier this year with the announcement of an integration with NVIDIA’s Isaac Sim extensible robotics simulator, powered by NVIDIA Omniverse. Explored more thoroughly on https://www.inorbit.ai/nvidiaisaacsim InOrbit is, simply put, leveraging the industry’s best photorealistic simulation tools to model complex environments and robot behaviors that closely match the real world.

Bringing RobOps and simulation together, especially those as advanced as NVIDIA provides, is no easy task, and our team was aided by collaborators at Ekumen, and NVIDIA. The work has paid off as the value gained by adding real-time 3D-modeled advanced simulation for robot orchestration, incident analysis, and fleet optimizations to InOrbit is proving to be enormous.

The conference held an interesting surprise when Jensen Huang, CEO and founder at NVIDIA explored the subject of automated warehouses and the future of robotics in his exciting keynote address. He discussed that they would necessarily be “software-defined”, with layered and collaborative systems for integration. As InOrbit CEO Florian Pestoni discussed this week in the Welcome to the Roboverse newsletter, this validated a concept InOrbit has been exploring for years around ‘Software-Defined X’.

|

|

|

InOrbit was fortunate to join the NVIDIA Robotics team at the GTC show to demo the latest updates in our efforts to bridge the Sim to Real domain gap. InOrbit's new "Real to Sim" widget used with Time Capsule provides a powerful tool for advanced incident management and fleet optimization.

Thank you to our partners, colleagues, and customers for joining us at MODEX and GTC. Sentiment aside, it's inspiring to see such innovation on display. These events take a lot of work, but they allow us to foster stronger connections, reinforcing our commitment to providing organizations with the best tools and insights to succeed in the constantly evolving world of robotics.

Find out what’s next for InOrbit, by following our social channels (LinkedIn, X, YouTube), and we’ll see everyone at the next conference. Spoiler: it's Automate 2024.